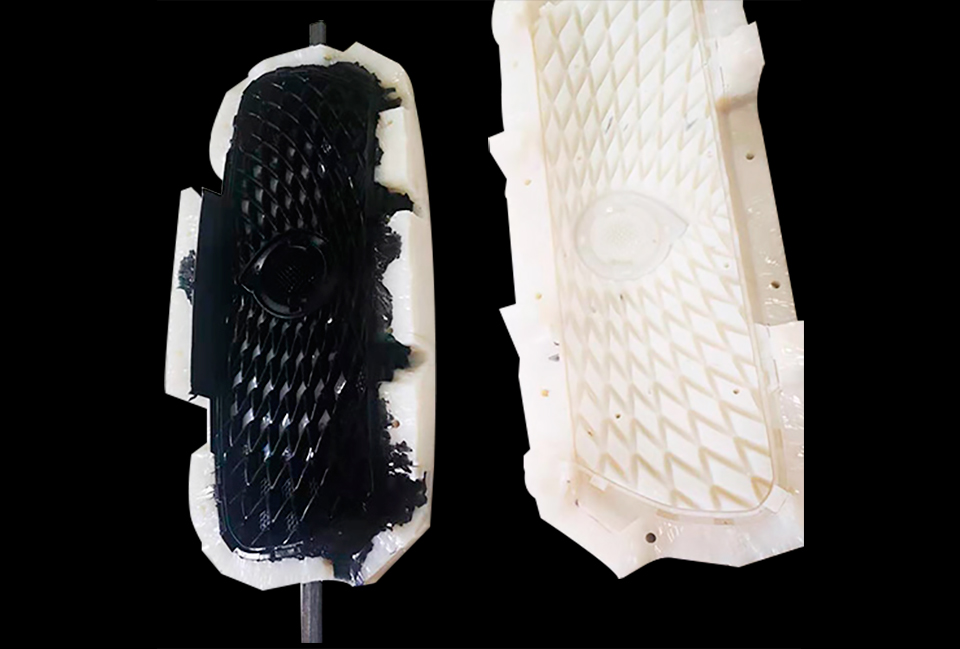

Silicone molding is also known as vacuum casting.

Liquid silicon rubber molding is a preferred manufacturing method for creating millions of different rubber parts, gaskets, valves, and much more. Silicone rubber has many advantages. Parts made using silicone have excellent resistance to the effects of temperature, electricity, and chemicals making them appropriate across a span of industries. Silicone also resists corrosion, temperature fluctuation, and electrical current placing the potential uses for liquid silicon rubber into the millions!